ADVANCED

CERAMICS

Pavezyum Technical Ceramics

PavTec

OXIDES

MgO (HEAVY)

Boron Carbide

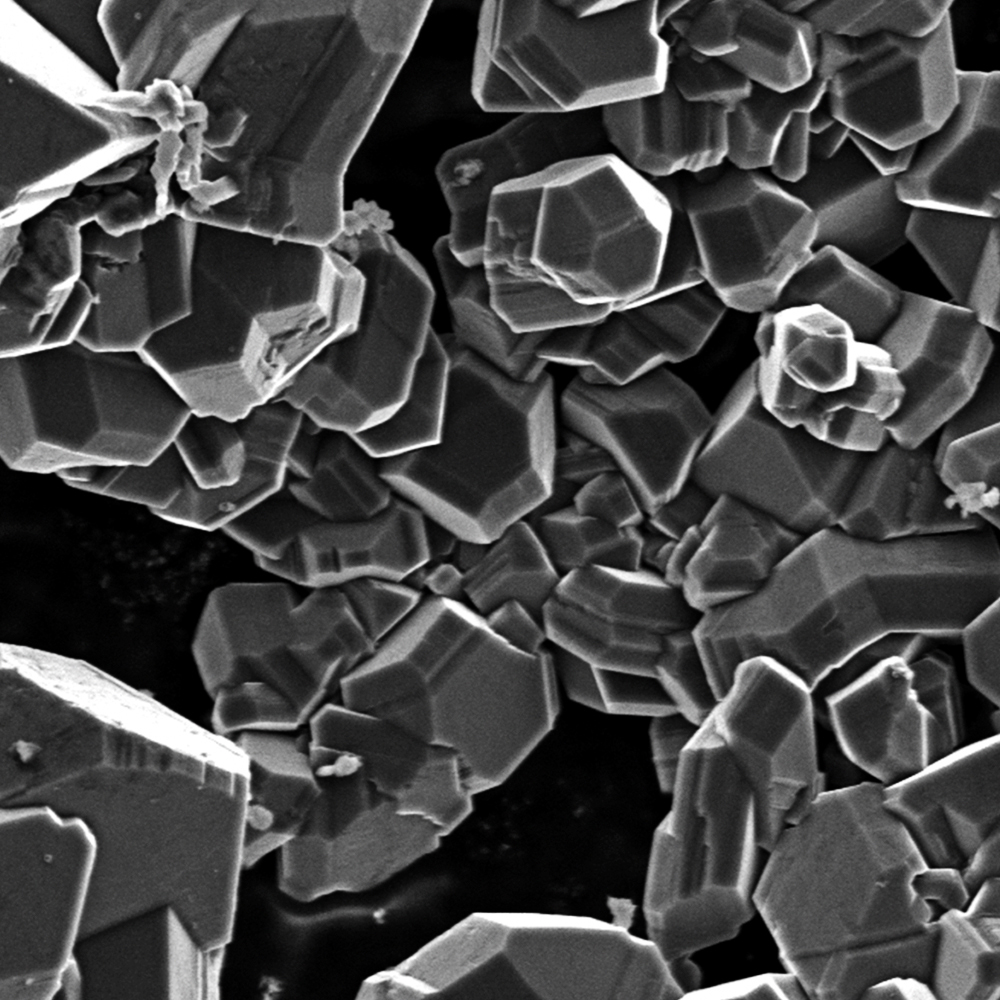

Boron Carbide is the 3rd hardest synthetic material after diamond and cubic boron nitride. Powder form is widely used as raw material for further synthesis reactions as boron source. It is converted into the hard plaques to provide protection in numerous applications. Large crystals are also used as abrasives.

Pavezyum initiated the Non-Sintered B4C production at the beginning of 2021. Non-Sintered ceramics are produced in the powder form without getting chunked or bulked.

Please contact us for product specifications

Titanium Diboride

Sustainable Production Line

High Electrical and Thermal Conductivity

Highest Melting Point among Borides

Oxidation Resistance under air up to 1100C

Please contact us for product specifications

Titanium Carbide

Abrasion resistance

Al-Alloy Hardening compound

Heat Shield Resistance Material

Please contact us for product specifications

Zirconium Diboride

Ultra High Temperature Ceramic Materials

Please contact us for product specifications

Zirconium Carbide

CerMat Component

High Corrosion Resistance at High Temperatures

Please contact us for product specifications

Magnesium Diboride

Superconductivity at Higher Applicable temperatures

such as Liquid Hydrogen Range

Please contact us for product specifications

Aluminum Diboride

Super Hard Ceramic

Ultra Incompressible Material

Military Grade Product

Please contact us for product specifications

Aluminium Dodecaboride

Sustainable Production Line

Ultra Hard Ceramic Material

Energetic Material

Please contact us for product specifications

Boron Nitride

CerMat Component

High Corrosion Resistance at High Temperatures

Please contact us for product specifications

![]()

Pure PowderElemental

Boron

![]()

Advanced CompoundsTechnical

Ceramics

![]()

Industrial SolutionsMetallurgical

Materials

We'll Ensure You Always Get the Best Result

Laboratory analysis may be carried out for a number of reasons – usually linked to ensuring a product has been manufactured to meet specifications and regulations and is safe to be released to the market.

Monitoring the quality of the analytical results, by using effective Quality Control (QC) tools, can help prevent good product being discarded and stop non-conforming product from being released.